TS-3 S

COMPACT ATTACHMENT

WITH OPTIMUM WEIGHT DISTRIBUTION

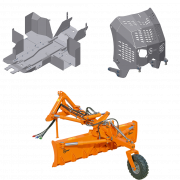

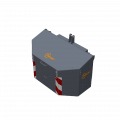

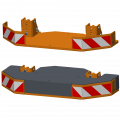

The TS-3 S is expecially for fine-grained dried and partially dried de-icing salt from silos and as bagged goods and is available with a capacity of 0,7 m³, 1 m³ or 1,5 m³. With the construction of the TS-3 S the main emphasis was put on a process and function based design. The spreader offers several features and is ideal for spreading material on streets, roads and parking lots. Developed with a focus on close attachment to the three-point linkage for optimum weight distribution, the implement offers the best possible ride on snow and ice covered surfaces.

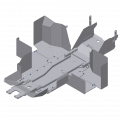

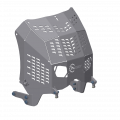

The conveyor screw and the protective grid in the body of the spreader are galvanized, all other parts are galvanized and painted. Spreading plate and deflectors are made of stainless steel V4A.

Standard specification

- Strong, galvanised and paint-coated hopper base

- Galvanised auger and hopper grid

- V4A stainless steel vanes and deflector

- Manual spreading pattern control

- Rubber curtain protects the vehicle

- Manual spreading rate and width control via spools

- High-quality, long-lasting and low-energy LED road lights

- Stand

| Type | TS-307 | TS-310 | TS-315 |

| Weight [kg] | 415 | 445 | 525 |

| Width [mm] | 2020 | 2020 | 2020 |

| Hopper volume [m³] | 0,7 | 1 | 1,5 |

| Spreading width [mm] | 1-8 | 1-8 | 1-8 |

| Salt spreading rate * [g/m²] | 5-100 | 5-100 | 5-100 |

*) density 15 kg / 10 l, spreading width: 5 m, driving speed: 9 km/h

Options

- TS-N proportional control unit

with electrical control panel for tractor cab (standard control) - TS-W path-dependent proportional control

with electrical control panel for tractor cab - pulses via standardized signal socket from the tractor (DIN 9684 / ISO 11786; is required on the tractor) - Speed sensor

for path-dependent control unit TS-W,

required in lack of signal socket - Outside temperature indicator with sensor

for path-dependent control - Filling level indicator

for path-dependent control TS-W - Spreading control with sensor

for path-dependent control TS-W - Electric spreading pattern control

(require TS-N or TS-W) - LED work light

(require TS-N or TS-W) - Flashing light

(require TS-N or TS-W) - V4A stainless steel auger

- Stirring unit for dissolving clumped spreading material

- V4A stainless steel stirring unit for dissolving clumped spreading material

- Tarp cover

- Remote oil supply by pto pump (additional weight 50 kg)

If combined with hydraulic self loading device, the distance between front pto and centre of tail hook of lower links, has to be min. 650 mm.

Control options

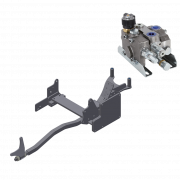

Proportiobal control unit TS-N

Electronic operation for the tractor cabin; microcontroller with adjustable values of spreading quantity and spreading width, ON/OFF switch, switch for working lights (optional), and regulation of the optional electrical spreading pattern adjustment with LED positioning display.

These parameters work independent from the driving speed of the vehicle.

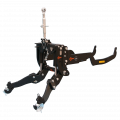

Path-dependent control unit TS-W

With the proportional control unit spreading width, spreading quantity and spreading pattern (optional with electrical spreading pattern) can be set. This works dependent on the driving speed.

On the touch screen there are different functions available, as for example for short-time maximum flow of spreading materials (e.g. for bridges), change between 2 spreading widths (e.g. side road and main road), 2 different presettings for spreading quantity (z.B. level road and ascending road) or for activating LED work lights.

With the 3 potentiometer you can adjust spreading quantity, spreading width and spreading pattern.